We understand that microwave PCB considers Dk (dielectric constant) and Df (loss tangent), so comprehensively evaluate and select high-performance materials such as PTFE (Teflon), PPO, CE, BT, etc.

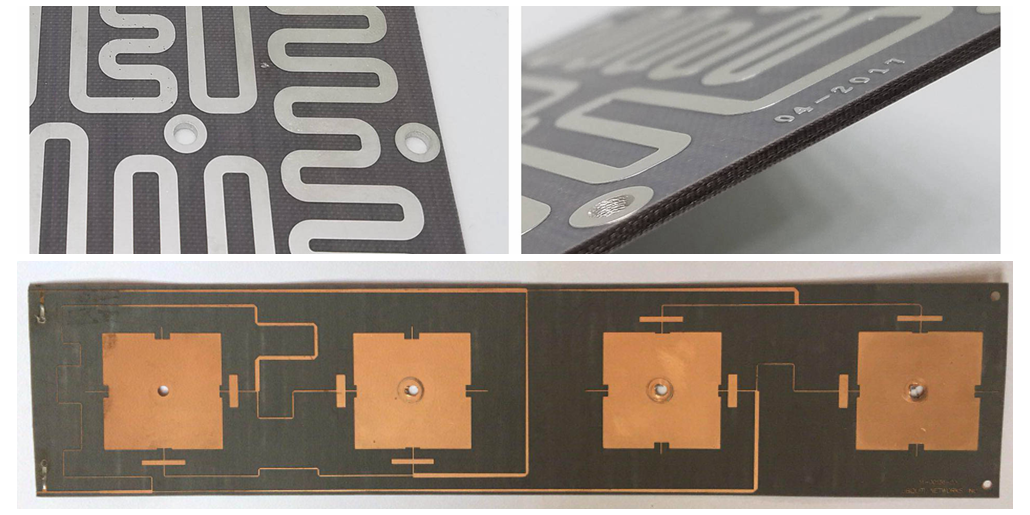

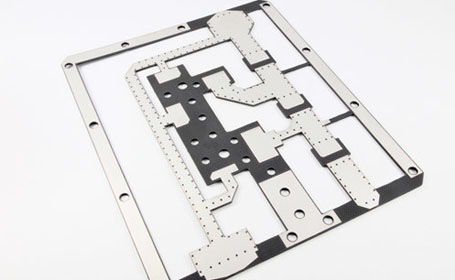

Q2: What kinds of raw material do you use? Surface finish: Has, Hasl lead-free, ENIG, OSP, IAg, etcĮlectromagnetic waves with a frequency greater than 1 GHz are called microwaves, and circuit boards made of high-frequency materials are just called microwave PCBs (high-frequency PCBs). They are often seen in RFID, remote base-stations devices. PS obtains raw materials from manufacturers that provide high-quality microwave PCB substrates, among which the famous ones are Rogers and Taconic.īase Material: Rogers, Taconic, Isola, Wangling, etc The market for microwave PCBs is growing very fast, in the fields of communications, medical, military, automotive, instrumentation, etc., according to predictions, microwave PCBs may account for about 15% of the total global amount after several years. It is the largest amount of materials are used to make microwave PCBs. Materials that can meet the requirements are such as ceramic, fiberglass, and PTFE (Teflon), among which, PTFE possess the lowest dielectric constant (typically 2.6~2.7) and the dielectric loss tangent (0.002). In order to achieve high-speed transmission, it is necessary to achieve low loss and low delay of the signals, so copper-clad laminates who having low dielectric constant and loss are needed. In the PCB industry, microwave PCB is another development trend in addition to HDI circuit board.

The microwave PCBs refer to the ones produced by a conventional rigid PCB manufacturing method on a specific high-frequency (>1GHZ) copper clad laminates.

0 kommentar(er)

0 kommentar(er)